News

-

Shrinkage test of pp woven sack tapes

1. Object of Test To determine the degree of shrinkage that will occur when polyolefin tape is subjected to heat for a specified length of time. 2. Method PP (polypropylene) woven sack tape 5 randomly selected tape samples are cut to the exact length of 100 cm (39.37”). These are then p...Read more -

Do you know How to Convert Denier of PP Woven Fabric to GSM?

Quality control is a must for any industry, and woven manufacturers are no exception. In order to ensure the quality of their products, pp woven bag manufacturers need to measure the weight and thickness of their fabric on a regular basis. One of the most common methods used to measure this is kn...Read more -

How to choose high quality polypropylene woven bags

The scope of use of polypropylene bags is very diverse. Therefore, in this type of packaging bag, there are several types with their specific features. However, the most important criteria for differences are capacity (carrying capacity), raw materials for production, and the purpose. The follow...Read more -

Coated and Uncoated Jumbo Bulk Bags

Uncoated Bulk Bags Coated Bulk Bags Flexible Intermediate Bulk Containers are typically constructed by weaving together strands of polypropylene(PP). Because of the weave-based construction, PP materials that are very fine may seep through the weave or sew lines. Examples of these products includ...Read more -

5:1 vs 6:1 Safety Guidelines for FIBC Big Bag

When using bulk bags, it is important to use the instructions provided by both your supplier and the manufacturer. It is also important that you don’t fill bags over their safe working load and/or reuse bags that aren’t designed for more than one use. Most bulk bags are manufactured for a single ...Read more -

woven sack production process

• How to produce for Laminated Woven Packing Bags Firstly we neeed to know some basic information for Pp Woven Bag With Lamination, Like • Size of the bag • Weight of bag required or GSM • Stitching type • Strength requirement • Color of the bag Etc. • Si...Read more -

How to decide GSM of FIBC bags?

Detailed Guide to Determining the GSM of FIBC Bags Deciding the GSM (grams per square meter) for Flexible Intermediate Bulk Containers (FIBCs) involves a thorough understanding of the bag’s intended application, safety requirements, material characteristics, and industry standards. Here’s an in-d...Read more -

PP(polypropylene) Block bottom valve bag types

PP Block bottom packaging bags are roughly divided into two types: open bag and valve bag. At present, multi-purpose open-mouth bags are widely used. They have the advantages of the square bottom, beautiful appearance, and convenient connection of various packaging machines. Regarding the valve s...Read more -

How many different kinds of coating film or laminated film in pp woven polybag

Mostly there have 4 kinds of coating film used in PP woven bags . The types of coating film and its properties are the initial requirements of a PP woven bag. These need to know before choosing the best film material. Depending on the user requirements, five types of coating film or laminated f...Read more -

Versatility of BOPP Woven Bags in the Packaging Industry

In the packaging world, BOPP polyethylene woven bags have become a popular choice for businesses looking for durable and visually appealing packaging solutions. These bags are made from BOPP (biaxially oriented polypropylene) film laminated to polypropylene woven fabric, making them strong, tear-...Read more -

why choose ad*star bag to pack dry mortar, gypsum packaging,cement.

For packaging materials of dry mortar, plaster and cement, choosing the right packaging bag is crucial to ensure the safety and quality of the product. Shijiazhuang Boda Plastic Chemical Co., Ltd. is a leading manufacturer with 20 years of experience in producing high-quality building material pa...Read more -

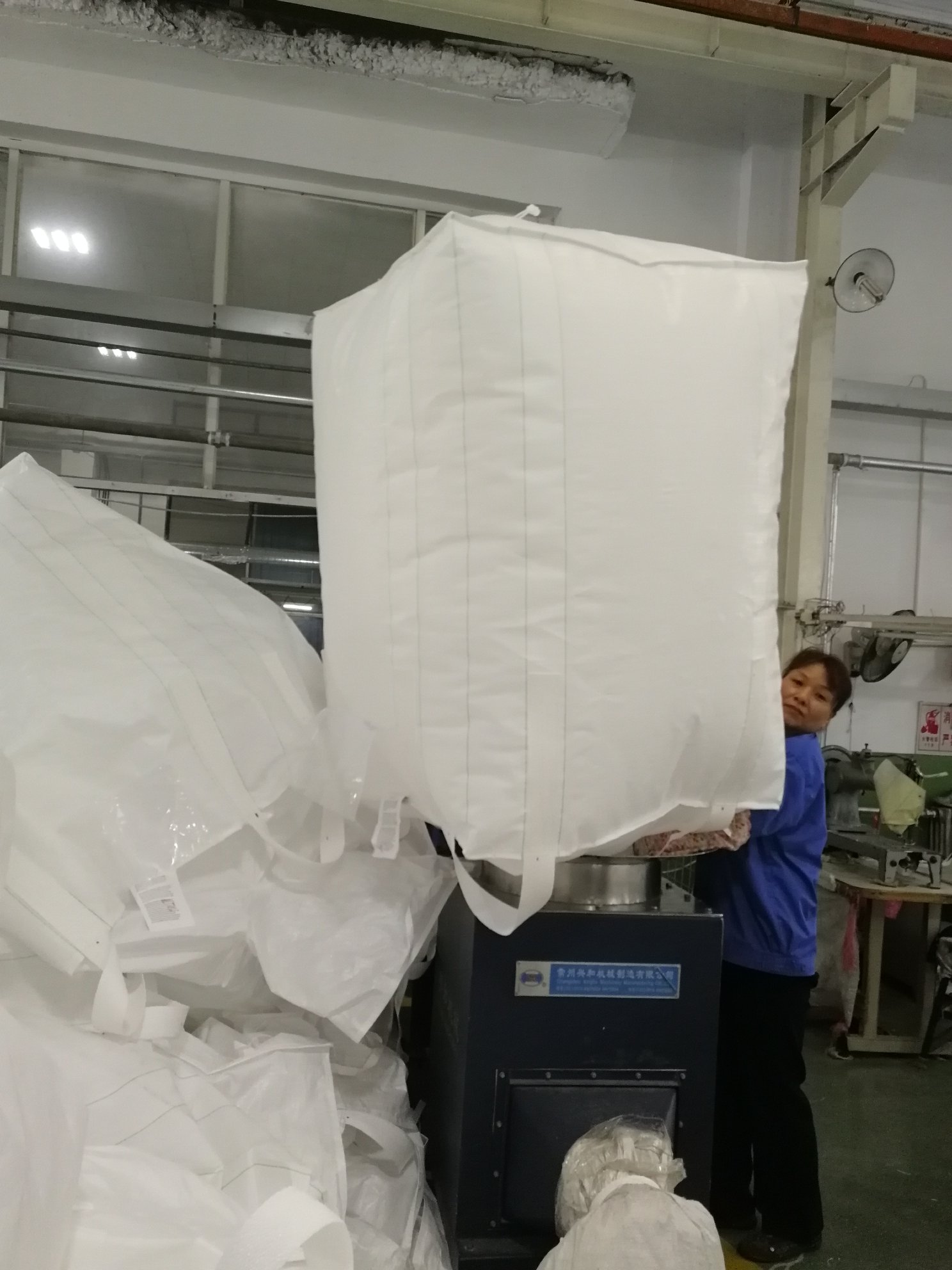

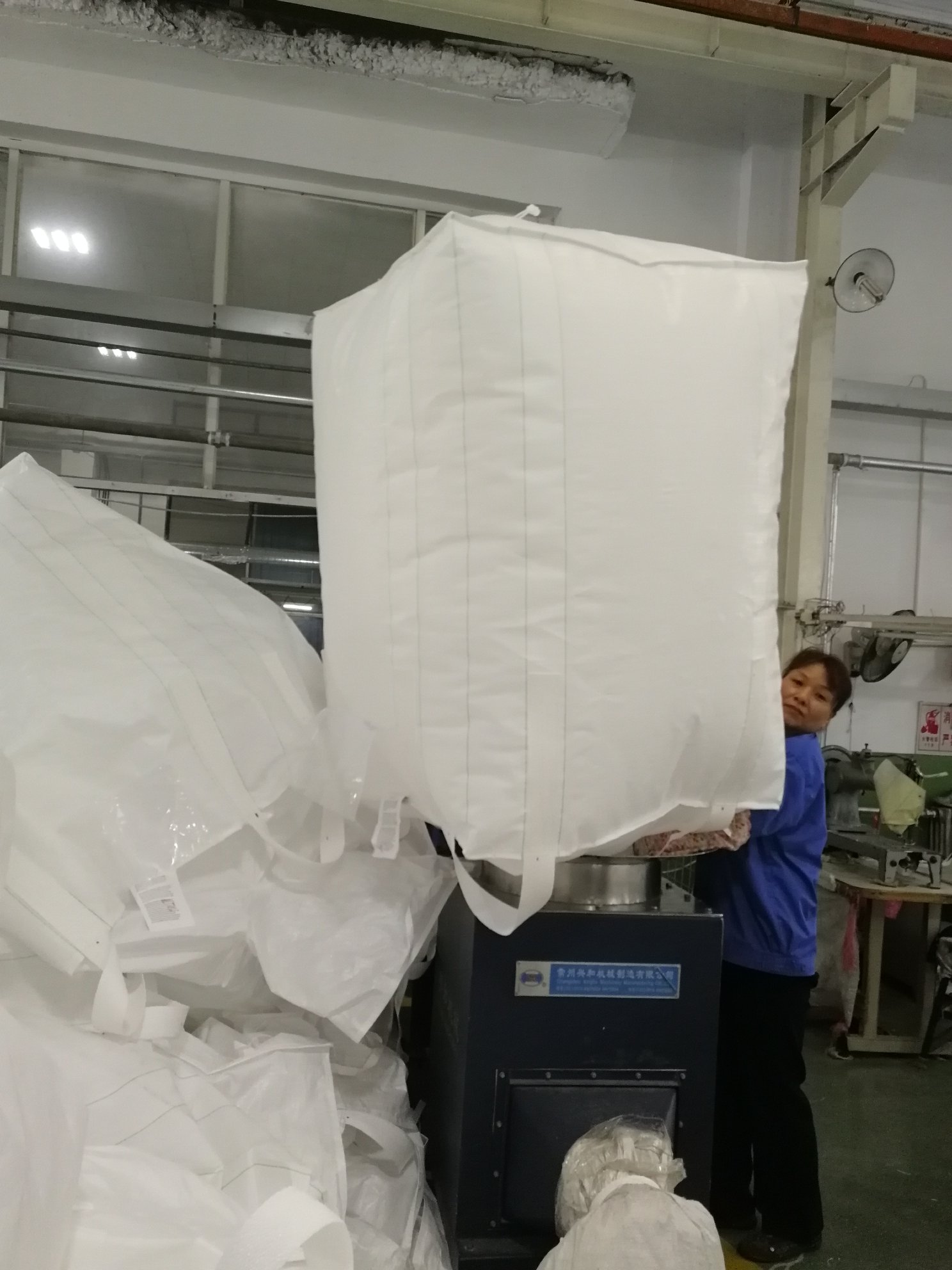

jumbo bag type 10: circular FIBC -duffle top and flat bottom

Round FIBC jumbo bags, Are a popular choice for transporting and storing a variety of materials. These giant bags are made from polypropylene, a durable and flexible material that can hold up to 1000kg of cargo. The round design of these FIBC bags makes them easy to fill and handle, making them a...Read more