OEM Factory for Pp Woven Inner Coated Sugar Packaging Bag - 25KG BOPP LAMINATED SACK WITH 3 COLORS PRINT – Jintang

OEM Factory for Pp Woven Inner Coated Sugar Packaging Bag - 25KG BOPP LAMINATED SACK WITH 3 COLORS PRINT – Jintang Detail:

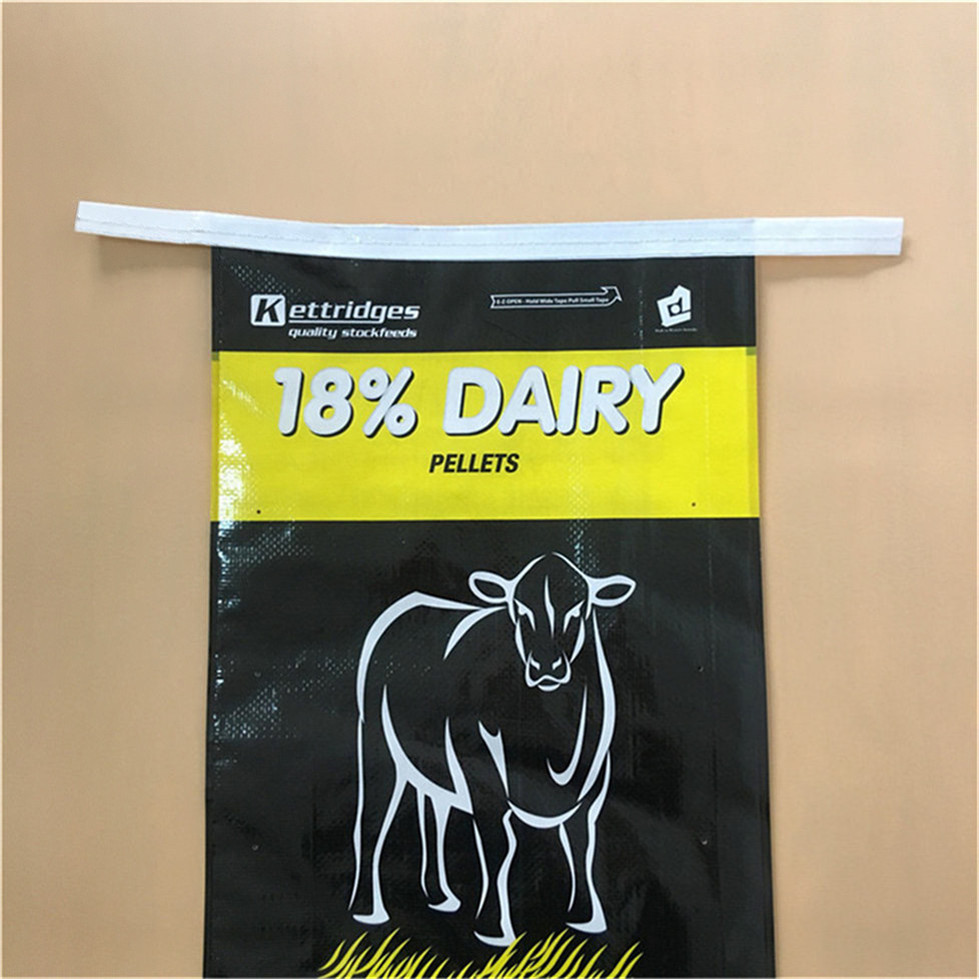

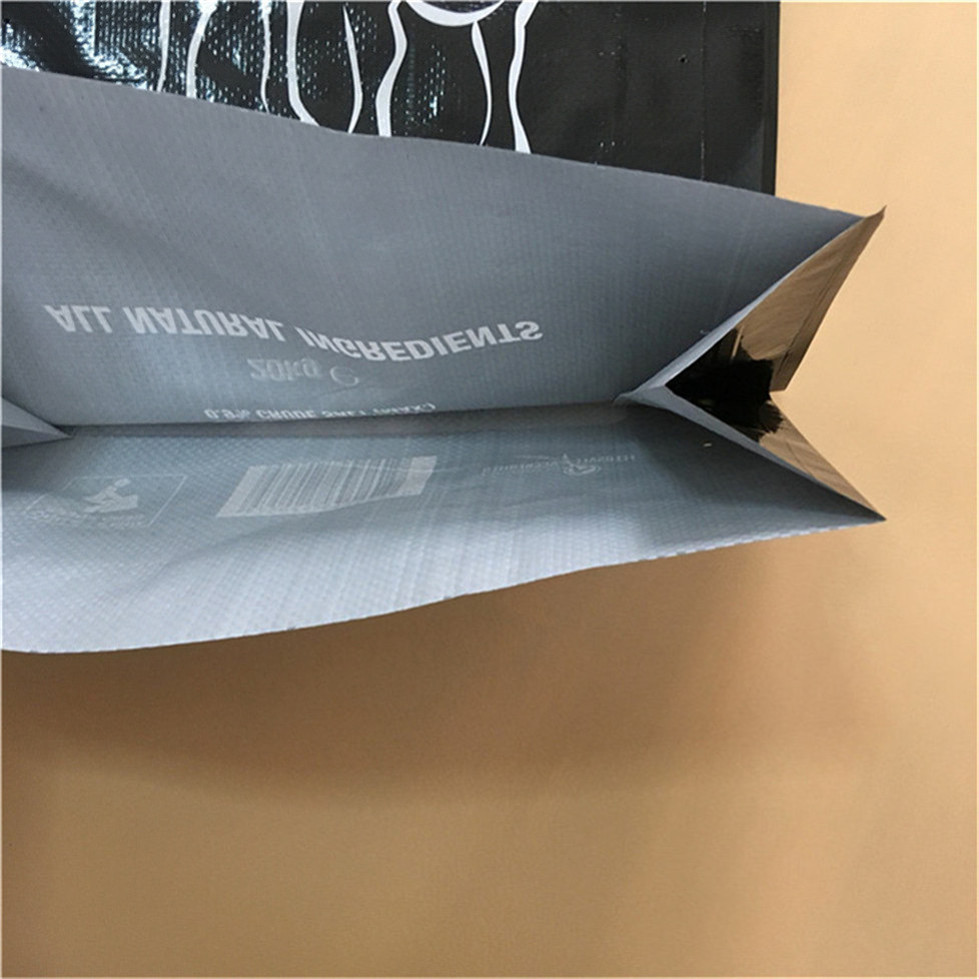

25KG BOPP LAMINATED SACK WITH 3 COLORS PRINT

| RAWMATERIAL | PP |

| BOPP LAMINATED | YES |

| FABRIC THICKNESS | 58-95GSM |

| WIDTH | 30-72CM |

| 7 COLORS | |

| CUSTOMIZED | YES |

| SAMPLE | FREE |

| MOQ | 50000PCS |

| DELIVERY TIME | 10-15DAYS |

| PRODUCTION CAPACITY | 100000PCS PER DAY |

| PACKAGING DETAILS | BALE |

This bag is well recognize for their Performance, Strict quality parameters are maintained to avoid spillage, leakage Etc.

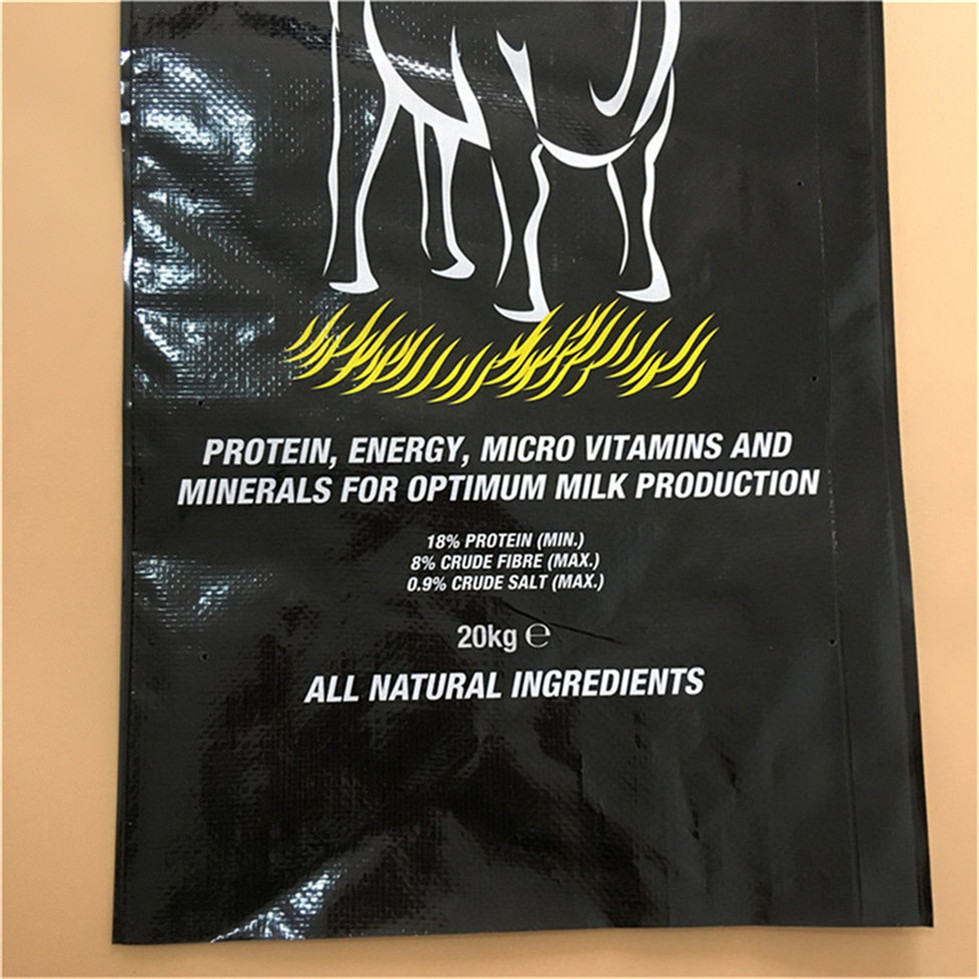

Equine nutrition Bag, Pet food Bag, Pig farming Bag, Poultry feed Bag, Sheep husbandry Bag,Sheep Goat Feed Bag,

Broiler Feed Bag.This Bags are widely used for packing Cattle feed Bag, Horse Food Bag, Dog food Bag, Bird food Bag, Cat food Bag,

Standardized food grade materials are using. Different sizes are supplying as per customer’s requirement.

25,50 Kg. Printed Cattle Feed & Animal Feed Bag, can be easily carried, so this is re-used for shopping and indirectly the brand is promoted,

bags with gussets as they are very useful while stacking in super markets or warehouses and they also occupy less space while transportation.

Shijiazhuang Boda Plastic Chemical Co., Ltd. was established in 2001,and currently has a wholly-owned subsidiary named Hebei Shengshi Jintang Packaging Co., Ltd,3 factories in total,Annual output value of 30 million U.S. dollars,

the first factory located in Shijiazhuang , the capital city of Hebei Province.

It occupies over 30,000 square meters and more than 300 employees working there,

the second factory located in Xingtang , the outskirt of Shijiazhuang city. Named Shengshijintang Packaging Co., ltd.

It occupies over 70,000 square meters and around 300 employees working there

the third factory, which also the branch of Shengshijintang Packaging Co., ltd.

It occupies over 130,000 square meters and around 300 employees working there.

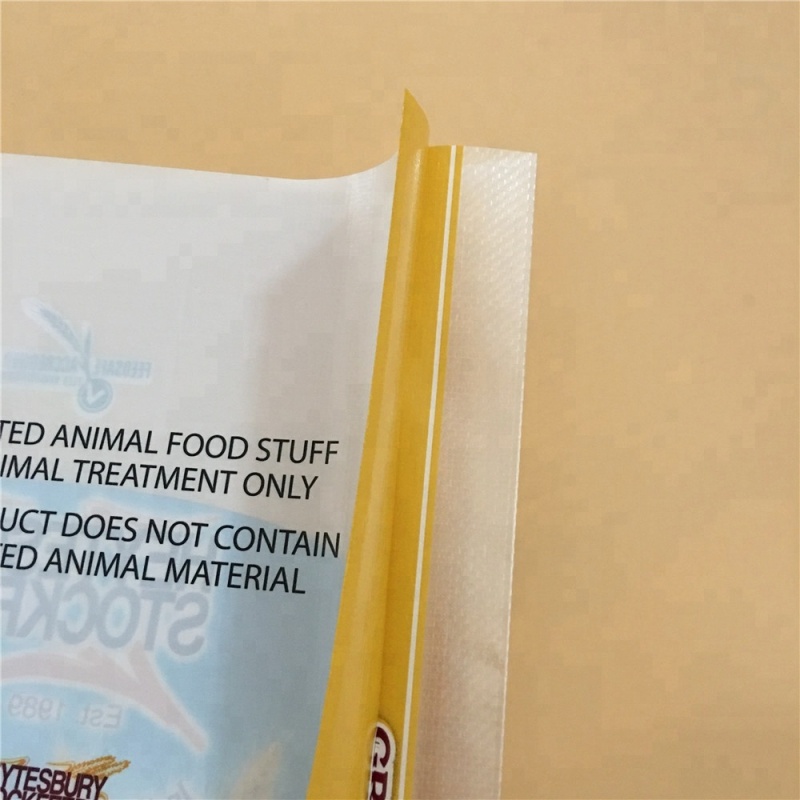

Product detail pictures:

Related Product Guide:

Troubleshooting during the production of woven bags

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for OEM Factory for Pp Woven Inner Coated Sugar Packaging Bag - 25KG BOPP LAMINATED SACK WITH 3 COLORS PRINT – Jintang , The product will supply to all over the world, such as: Johor, United Arab emirates, Georgia, With the advanced workshop, professional design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our products are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.